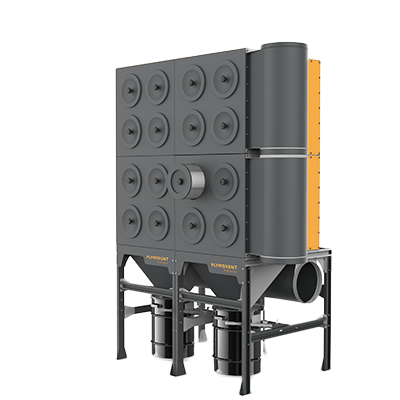

SCS

The SCS is a central filter system for removing fumes released during welding, cutting and grinding processes in the metalworking industry.

It is optimized for welding fume extraction systems that require extraction arms with a flow rate of up to 7000 m3/h and general filtration systems such as push-pull systems with a flow rate of up to 9000 m3/h. RoboCleanPlus automatically cleans the filter cartridge when the SCS is turned on.

The SCS filter system is fairly easy to install. The eight air inlet positions and two air outlet positions make the unit very flexible. As the compact SCS filter system requires little floor space, the unit can be used in various settings.

- Source extraction by means of extraction arms

- Isolated work area by means of an extraction hood

- General filtration system* to control the background concentration of welding fumes

Self-cleaning

The SCS filter system is fitted as standard with RoboCleanPlus. This self-cleaning system cleans the filter cartridge automatically, section wise, through shots of compressed air. Dust and particles fall into the 100L waste container underneath. Besides the user-friendly part, the self-cleaning system also increases the lifespan of the filter cartridge as dust and metal particles are being constantly removed from the filter surface, reducing maintenance and replacement costs.

Compact unit

The SCS filter system features a vertically placed filter cartridge. Although the 150 m2 filter surface is large, the SCS unit is small in volume, occupying little floor space.

Energy saving

Using a SCS unit in your welding fume extraction system saves energy if recirculation is allowed (depending on local regulations). Recirculation reduces the need for ventilation with outside air. Expensively heated or cooled air stays within the workshop, reducing both general and technical costs and the impact of operations on the environment.